The NEW 208HRD-180 High Resolution Sputter Coater from Cressington offers real solutions to the problems encountered when coating difficult samples for Thin Film and FE-SEM applications. This system features a smaller 28mm diameter target to better utilize more expensive materials such as iridium for FE-SEM, or a wide range of materials for Thin Film applications. This system has a large 180mm OD vacuum chamber that can accommodate up to a 6” wafer, along with a sputter head and rotary stage that can both be tilted to give increased uniformity over larger samples.

The 208HRD-180 High Resolution Sputter Coater is a complete coating solution, including as standard:

- Pumping system consisting of turbo pump, dry (diaphragm) backing pump for turbo, and vacuum connections

- MTM-20 High Resolution Film Thickness Controller1

- Rotary-Tilting (RT) Stage with five rotation speeds that can be manually tilted to set angles

- Large target selection including iridium, aluminum, platinum, gold, palladium, titanium, chromium, indium tin oxide (ITO). See here for full list of targets.

|

|

|

MTM-20 High Resolution

Thickness Controller |

|

Rotary-Tilting RT Stage

demonstrating

variable speed settings and adjustable tilt. |

Main Features:

- Wide choice of Coating Materials. Magnetron head design and effective gas handling allow for a wide choice of target materials .

- Economical target utilization. The 208HRD-180 offers a smaller diameter target and modified chamber configurations to give more economical usage for costly materials like iridium.

- Novel Sputter Head Design. Plug-in sputter head (one included) can be offset and tilted. Plug-in design makes it easy to switch between target materials.

- Large Chamber and Rotary-Tilting Stage: 180mm (7") OD Chamber can accommodate samples up to 6" in diameter.

- Precision Thickness Control. Thickness optimized for FESEM application using the MTM-20 High Resolution Thickness Controller1, which has a resolution of 0.1nm. This enables precise and reproducible thin coatings, especially in the range of 0.5 - 3nm, a thickness desirable for FESEM applications.

- Variable Chamber Geometry. Chamber geometry is used to adjust deposition rate to optimize structure. Height can be adjusted by the addition of metal spacer rings (2 included).

- Compact, Modern, Benchtop Design. Space and energy saving design eliminates need for floor space, water or specialized electrical connections. Integrated turbo pump ensures fast pump down combined with high positive pumping speed during sputtering process. Integrated turbo pump ensures fast pump down speed. The backing pump for the turbo is a diaphragm pump, giving oil free operation.

208HRD-180 Sputter Head

The 208HRD-180 has a compact 28mm diameter target design that offers higher efficiency to better utilize target materials which is beneficial for depositing expensive materials like iridium for FE-SEM applications, or when depositing thin films. Additionally, this larger chamber system has plug-in sputter head allowing quick changes between materials. The sputter head can also be offset and tilted which, in conjunction with tilting stage, gives improved coating uniformity over larger samples.

|

|

The Sputter Head on the 208HRD-180 utilizes a

28mm diameter target and can be offset (left) and tilted (right). |

Wide Range of Coating Materials for Thin Film and FE-SEM Applications:

- Wide range of target materials available including iridium, gold, platinum, palladium, copper, silver, titanium, chromium, indium tin oxide (ITO), aluminum, cobalt, nickel, tantalum, and tungsten. See full list here.

- Iridium is a very fine grain coating material, excellent for high resolution imaging, but expensive. The smaller 28mm diameter target better utilizes iridium, and has less up-front costs compared to larger diameter targets.

- With optimized parameters, few hundred nanometer films of more difficult to sputter materials like aluminum are possible.

208HRD-180 Chamber

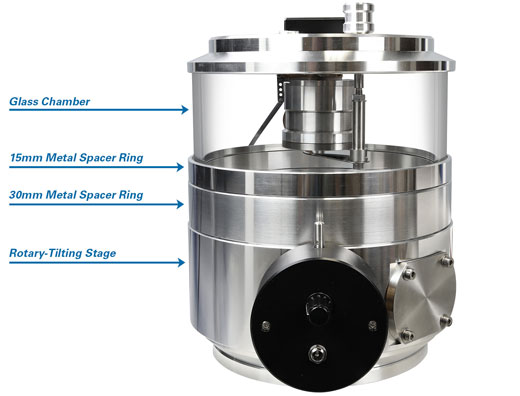

The 208HRD-180 has a modular chamber that consists of 180mm OD glass chamber, metal spacer rings (two included, 15 and 30mm tall), and Rotary-Tilting Stage. These components are labeled in the image below.

|

| 208HRD-180 Chamber Components |

The sputter head support pillar can be adjusted into three different positions, varying the overall chamber height. Each adjustment location corresponds to a different metal spacer/ glass chamber / Rotary-Tilting stage configuration. The addition of a spacer ring above the RT stage increases the deposition distances by 15mm or 30mm (one of each included).

|

|

|

| Chamber configuration variations |

|

Pillar height |

|

Specifications for the 208HRD-180 High Resolution Sputter Coater

Ordering Information

| Prod #

| Description

| Unit

| Price

| Order / Quote

|

| 115V System

|

| 8000HRD-180

| 208HRD-180 High Resolution Sputter Coater for FESEM, 115VAC, 50/60Hz, Specify target choice

| each

| P.O.R.

|

|

| 220V System

|

| 8000HRD-180-220

| 208HRD-180 High Resolution Sputter Coater for FESEM, 220VAC, 50/60Hz, Specify target choice

| each

| P.O.R.

|

|

| Accessories and Spares:

|

| 9611

| Filter for Venting Inlet, complete with 1/4" hose for 108Auto, 108Auto/SE, 108Carbon, 108Carbon/SE, 208HRD, and 208C

| each

| 14.25

|

|

| 93008

| Replacement Crystals for MTM-10/20

| pkg/3

| 42.00

|

|

| 93009

| Replacement Crystals for MTM-10/20

| pkg/10

| 93.30

|

|

| 896

| PELCO Bell Jar Kleen™, 14 oz.

| each

| 14.36

|

|

| 7032

| Argon Pressure Regulator Kit, including dual stage pressure regulator, 3m gas hose and 2 hose clips for 6mm tube fittings

| each

| 610.00

|

|

| 208HRD-180 Rotary-Tilting Stage Sample Tables

|

| 7050-PIN

| Sample Table for 4 x 12.7mm Ø Standard Pin Stubs

| each

| 76.25

|

|

| 7050-10

| Sample Table for 4 x 10mm Ø JEOL Cylinder Mounts

| each

| 85.00

|

|

| 7050-12

| Sample Table for 3 x 12mm Ø JEOL Cylinder Mounts

| each

| 85.00

|

|

| 7050-15

| Sample Table for 3 x 15mm Ø Hitachi M4 Mounts

| each

| 85.00

|

|

| 7050-32

| Sample Table for 32mm Ø Metallographic Mount

| each

| 85.00

|

|

| 9660-S

| Sample Table for Standard 1 x 3" Glass Slide or 3" Wafer

| each

| 245.00

|

|

| 9660-80

| Sample Table for Two Petrographic Slides, 26 x 46 to 28 x 48mm

| each

| 293.00

|

|

| 9660-100

| Replacement Large Sample and 4" Wafer Table

| each

| 315.00

|

|

| 9660HRD-S

| Slide Frame Holder to secure three standard slides to 9660-100

| each

| 135.00

|

|

| 9660HRD-130

| 5" Wafer Table, not compatible with MTM-20 Thickness Controller

| each

| 390.00

|

|

| 9660HRD-153

| 6" Wafer Table, not compatible with MTM-20 Thickness Controller

| each

| 475.00

|

|

1The MTM-20 Thickness Controller is not compatible with samples over 4" diameter.

Ted Pella, Inc has been an authorized distributor, including exclusive in the Americas, for the complete range of Cressington vacuum coating systems for over 25 years. Cressington Scientific Instruments Ltd, based in Watford, UK develops, designs and manufactures vacuum coating systems for scanning electron microscopy (SEM), transmission electron microscopy (TEM) specimen preparation and thin film research applications. Core competencies of Cressington are vacuum technology, DC magnetron sputtering technology and thermal evaporation. The Cressington products range comprises 108 series sputter coaters for standard SEM sample coating, the 108 series carbon coaters for standard EDX coating, the 208HRD for field emission SEM (FESEM) sample coating, 208HRD for FESEM imaging and thin film applications, and the 208C high vacuum turbo carbon coater for TEM/EBSD/microprobe carbon coating. Cressington takes pride in building products which have excellent quality, are compact bench-top systems and are easy to use.