|

|

|

|

|

|

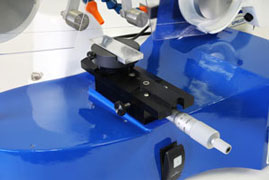

Standard configuration

for wax mounts |

|

With optional 3-axis Goniometer |

|

With optional Vise Holder |

The PELCO® Precision Wire Saw™ is capable of cutting a variety of materials while minimizing damage from the cutting process using a gentle lapping action. This gentle action combined with high precision and low kerf damage makes the Diamond Wire Saw ideal for slicing samples where minimizing mechanical damage and precise positioning of the cut are critical. This wire saw is an updated version of the South Bay Technology Model 850 Abrasive Slurry Saw / Wire Saw.

The saw can be used either with abrasive slurry or with a Diamond Embedded Wire. It can cut brittle samples, which would otherwise be damaged using Low Speed Diamond Saws. With precision and control, the Diamond Wire Saw can cut materials such as sapphire, silicon, glass and germanium as well as tough materials such as tungsten, aluminum, brass and steel. It is highly useful for cutting fragile crystals, substrates with delicate layers, or any material that might otherwise be damaged using other cutting methods.

A variety of sample holders and fixtures are available for use with the PELCO® Precision Wire Saw™ and enable it to cut virtually any sample geometry without difficulty. Oriented crystals, awkward geometries, or flat samples can all be cut using the various holders available. An inspection microscope attachment is also available, for extra precision and additional ease for alignment of difficult samples. The PELCO® Precision Wire Saw™ can also be used as a string saw to cut water-soluble crystals. Whatever the application, the Wire Saw can be a valuable tool in the preparation of all sample types. With the addition of precision goniometer fixtures, it is also ideal for working with single crystals and optical components.

The saw comes equipped with a recirculating system for abrasive slurry or coolant. It consists of a peristaltic pump and a continuously mixed reservoir. It allows for continuous recirculation of cutting slurry when using plain stainless wire blades, or cutting fluid when using diamond wire blades.

Operation

In general operations, a sample is mounted to an aluminum or graphite sample mount and placed on the work table. The work table is mounted on a micrometer-controlled indexing cross-feed to allow precise, parallel slices to be taken. An appropriate load is applied by adjusting the weight on the wire arm. Cooling liquid/abrasive is applied using the supplied recirculating cooling/slurry supply system. Many different work tables are available for different sample types, including everything from the aluminum or graphite mounts for wax mounting; to a simple vise; to a complete 3-axis goniometer with rotation and 2 tilt axes suitable for cutting and shaping single crystals. An optional adjustable attached optical microscope for greater precision when setting up and monitoring cutting is also available.

A continuously mixed recirculation system is used for cutting fluid or abrasive slurry. Slurry flow is controlled by an included peristaltic pump unit. The PELCO® Precision Wire Saw™ is also compatible with the PELCO® Abrasive Dispenser for sensitive operations where continuous or timed application of fresh abrasive is needed.

Cutting Blades

The PELCO® Precision Wire Saw™ uses wire loop blades. Either Diamond-embedded Stainless Steel wire blades or plain Stainless Steel wire blades may be used, depending on whether an abrasive slurry is used for cutting. Blade diameters of 0.010 and 0.015" are available. The wire blades can be easily changed and appropriately tensioned within a few moments.

Specifications

| Overall Dimensions: |

28 x 9 x 11" L x W x H |

| Electrical: |

100-240 VAC 50/60 Hz Universal Power |

| Maximum Sample Diameter: |

2.5" (63mm) |

| Wire Speed: |

25-250 in/sec (40-475 RPM) |

| Cross Feed Range: |

2" (50mm) maximum |

| Micrometer Feed: |

0-25mm at 0.01mm increments |

Features

- Very gentle, low damage cutting for many types of materials and single crystals

- Easily replaceable wire blades with adjustable tensioning mechanism

- Recirculating slurry/coolant system included

- ETL and CE certified

- A wide variety of sample holders allow mounting of virtually any sample shape

- Multi-axis Precision Goniometer available for single crystal cutting and other demanding tasks

- Optional Inspection Microscope available

Accessories

|