Precision hand lapping fixtures allow for the preparation of planar, parallel, and highly polished surfaces on metallographic specimens, single-crystal wafers

and semiconductors, glasses, rock samples, and other materials.

Lapping processes are also used to generate highly parallel, smooth faces, and to thin specimens to a precise target thickness.

They may aid greatly in avoiding rounding or overpolishing

when a hard material is embedded in a softer matrix, such as

in epoxy-embedded samples. This is particularly useful in hand polishing semiconductors, optical components, and for thinning TEM specimens before finishing via dimple polishing.

PELCO® lapping fixtures allow for lapping of samples from <1/8" (3mm) to 1" (25mm) in diameter, and up to 1/2" (13 mm) thick. Micrometer and shim-controlled versions are available. Fixtures are equipped with tungsten carbide feet, which are highly resistant to wear from the lapping process. They can be used with the PELCO® Lapping Tray below, or with most grinder/polishers. Accessory sample mounts are available for the PELCO® 15000 Lapping Fixture which are directly compatible with the PELCO® Dimpler™ and the PELCO® Video Alignment Microscope and can be transferred without demounting the sample.

|

|

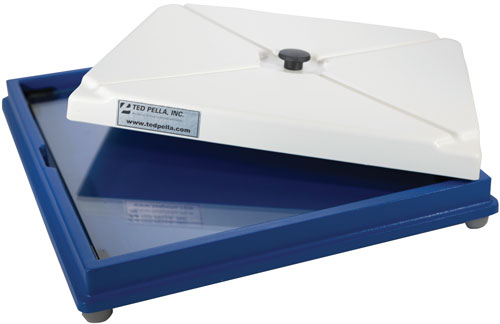

PELCO® Lapping Tray

The PELCO® Lapping Tray is a convenient solution for hand lapping or polishing with any of the PELCO® 14100, 14500, 15000 Lapping Fixtures and with the PELCO® Tripod Polisher™ 590. It provides a smooth, flat, and stable polished glass surface for lapping in a convenient catch tray for the used lapping fluid, allowing for easy cleanup after processing is complete.

The lapping surface is 12 x 12" (300 x 300mm) square. |

|