Pattern Design

The MRS-6 is fabricated by using the highest accuracy electron direct write

semiconductor manufacturing equipment available today. The pattern is built on a

silicon wafer with a 15nm Cr film. This film, which is significantly thinner that

that of the MRS-5 has superior edge quality. Imaging contrast in both secondary

and backscattered electron mode is possible with field emission SEMs and newer

tungsten or LaB6 SEMs. The overall size is ~ 3.2mm X 3.2mm X 0.5 mm thick.

The MRS-6 is fully conductive. No coatings are required or desirable. The

standard can be cleaned using a low power plasma etcher with oxygen gas.

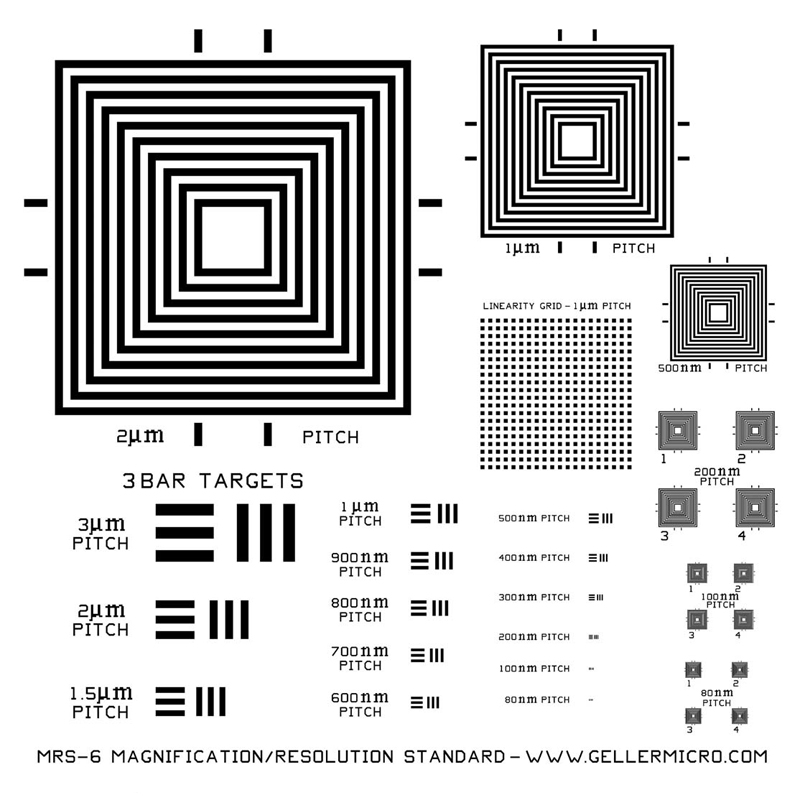

The geometric design of the MRS-6 and MRS-5 are the same. There are three

different types of patterns.

-

Groups of nested squares spanning several orders of magnitude with

pitches of 80nm, 100nm, 200nm, 500nm, ½µm, 1µm, and 2µm.

To allow for more testing the 80, 100 and 200nm patterns are repeated four times.

-

incorporated into the standards is an extension of the 1951 USAF 3-bar

targets. These finer patterns have pitches ranging from 80nm to 3µm in

15 steps. They will find good use measuring the resolution of state-of-the-art

optical microscopes (UV, confocal, laser scanning, etc.

-

The ½µm square test pattern will help analyze your images for all

types of dimensional distortions, vibrations and magnetic fields. This

pattern contains ½µm squares with a 1µm pitch over a 20µm X and Y

field.

Measured and certified are pitches (the distance between repeating parallel lines using

center-to-center or edge–to-edge spacing). These are the only type of

measurements that can be used to relate measurements from different microscopy

techniques (see "Submicrometer Linewidth Metrology in Optical Microscopy",

Nyysonen & Larrabee, Journal of the Research of the National Bureau of

Standards, Vol. 92, No. 3, 1987). Linewidth measurements (the measurement of a

single line or space width) can only be related if the same type of illumination is

used as for the calibrating instrument since edge effects lead to uncertainty in the

edge locations. Using pitch measurements, errors from edge-to-edge locations

cancel as long as like positions are measured.

Square boxes and the 1µm pitch square test patterns are used for measuring

magnification simultaneously in the X and Y directions. This gives a measure of

image skew, barreling, pincushion and other non-linearity's which can have

various origins, such as from stray magnetic fields. With the MRS-6 we have

provided a large range of pitches to closely match the needs of your

instrumentation.

The largest pattern has an overall dimension of 40µm square. It contains lines and

spaces that are nominally 1µm wide. This can be used to check magnifications

greater than 1,000X. The smaller patterns allow calibrations up to 1,000,000X.

The 3-bar targets were included as a response to many requests for a standard

capable of measuring resolving power for patterns smaller than the 1951 USAF

targets (see

http://www.efg2.com/Lab/ImageProcessing/TestTargets/).

They are often found covering a range of 0.25 to 228 cycles/mm. The standard target

element consists of two patterns (two sets of lines) at right angles to each other.

Each consists of three lines separated by spaces of equal width. The bar length to

width ratio is 5X. The patterns change size exponentially in groups and elements.

The range in line length for the original target was from 10mm to 0.08769mm.

Others have expanded the range towards finer patterns. We now extend the range

to a line width of 0.00004mm! With these 15 patterns measurement of modulation

transfer functions is made much simpler.

The patterns can also be used for determining imaging and chemical spatial resolution and chemical mapping.

|

Pattern

|

Pitch Spacings

|

Nested

boxes |

2µm |

1µm |

500nm |

200nm

4 each |

100nm

4 each |

80nm

4 each |

3 bar

targets |

3µm |

2µm |

1µm |

1.5µm |

1µm |

900nm |

3 bar

targets

continued |

800nm |

700nm |

600nm |

500nm |

400nm |

300nm |

3 bar

targets

continued |

200nm |

100nm |

80nm |

|

|

|

Traceability

Scanning electron microscope, 80nm pitch

(in-lens secondary electrons)

|

|

Scanning electron microscope, 80nm pitch

(type I secondary electrons)

|

Why should you consider a traceable standard? Beyond the requirements of

national and international quality standards, purchasing a CRM (certified

reference material) from a national laboratory or a traceable standard from a

certifying body (such as Geller MicroÅnalytical Laboratory) guarantees

dimensions. Most commercially available standards have unknown accuracies.

Measurements determined by optical methods measuring pattern frequency do

not tell you about the individual variations in pitch measurements- and this is

what you image. The MRS-6 is offered with or without traceability. The nontraceable

standard differs only in documentation and cost. Traceability in the X

and Y dimensions is established from a MRS-5 that has been measured by NPL

(National Physics Laboratory), the NIST counterpart in the U.K. We are in the

process of having the MRS-6 measured by a national laboratory and expect

measurements with lower uncertainties. The non-accumulative 2σ pitch

uncertainty is ±3 nm. Through international agreements our ACLASS

accreditation provides equivalency with NAVLP and A2LA. See

http://www.gellermicro.com/quality_control/QC.html.

Through national laboratory mutual recognition agreements NPL measurements are equivalent to NIST.

Traceable measurements are only provided for the 2, 1 and 0.1 μm pitch patterns.

Details can be found on the provided measurement certificates.

Recertification Program

We are often asked why the MRS needs re-certification. Under ISO-17025

guidelines your quality department should determine the re-certification interval

as they are most familiar with your company's quality system requirements.

Recertification is a common practice for devices such as gage blocks and electronic

instruments. Over the years we have found several standards which could not be

recertified due to physical damage and excessive contamination. In a few cases

we have seen electron beam damage and corrosion from storage in a

contaminating environment. Re-certification insures your standard will perform

its proper task and that you will be meeting your quality system directives.

Recertification includes cleaning.

Magnification Measurements

Optical Microscope magnifications can be measured only in the reflection

mode by directly on viewing CRTs, in reticles mounted within the ocular, or

directly on photomicrographs. Please note the contrast is not particularly high.

For instruments with verniers or electronic calipers distance measurements can

be verified using a pitch pattern of appropriate size. Magnification is simply the

image size divided by the object size (be careful to use the same units).

Scanning Electron Microscopes and FIB/SEMs can use the secondary electron signal at an

accelerating voltage of <=25keV preferably with type II secondary electrons to

get more of a surface image. Backscattered electron imaging is possible but only

for high sensitivity detectors.

To avoid pattern damage use <1 nA electron beam current.

Scanning Probe Microscope operators must be aware of the fine dimension of

the pitch patterns. The 80nm pitch has a nominal space width of 40nm. The

cantilever tip must be smaller to define the pattern. As shown in the AFM image

to the left the pattern lines have variable height.

Retainer & Mounting Options for SEM

|

The MRS-6 Calibration Standard comes unmounted to give the customer the flexibility to mount the

standard on the position or stub they wish.

We offer two retainer & mounting options; MRS-6 on either Ø1/2" (12.7mm)

pin stub or Ø15mm Hitachi mount. These mounting options have to be ordered additional

to the MRS-6 at the time of ordering.

|

International Calibration Standards

- ASTM E766–2003: Standard Practice For Calibrating The Magnification Of A Scanning Electron Microscope

- ISO 16700:1994 MICROBEAM ANALYSIS — Scanning Electron Microscopy — Guidelines For Calibrating Image Magnification

- There are no international standards for SPM magnification calibration at this time